Glossary

GLOSSARY

Stainless Steel is a generic term for a family of corrosion resistant iron (FE) based alloys containing 10.5% or more chromium (Cr). Chromium produces a thin layer of oxide on the surface of the steel known as a passive layer. This prevents further corrosion of the surface. Increasing the amount of chromium strengthens the passive film, hence increasing the level of corrosion resistance.

Other elements such as molybdenum (MO) and nitrogen (N) further strengthen the passive film and improve corrosion resistance. If the passive film is removed or damaged, it will spontaneously re-form in the presence of air or water.

For further information refer to ASSDA

There are many benefits of using stainless steel over galvanised wire;

- Corrosion resistance

- Fire and heat resistance

- Hygiene

- Aesthetic appearance

- Strength-to-weight advantage

- Ease of fabrication

- Impact resistance

- Long term value

- Life Cycle of Stainless Steel

Stainless steel can be classified by its crystalline structure into three main categories, austenitic, ferritic and martenstic. Austenitic stainless steel is the most commonly used stainless steel.

Austenitic stainless steel has nickel added so the crystal structure changes to ‘austenite’. The basic composition of austenitic stainless steel is 18% chromium and 8% nickel.

Grade 304 & 316 are austenitic stainless steel.

Properties of Austenitic Stainless Steel

• Excellent weldability

• Excellent corrosion resistance

• Excellent cleanabilty and hygiene characteristics

• Good high and excellent low temperature properties

• Non magnetic (if annealed)

• Strength and hardness increased by cold work

The major difference between Grade 304 and Grade 316, is that Grade 316 has the addition of molybdenum to its chemical composition, which greatly improves its resistance to corrosion, particularly to pitting.

Grade 316 has excellent resistance to corrosion in sea water. Please be aware that stainless steel still requires cleaning, a simple soap solution will keep your stainless steel sparkling.

Grade 304

18-20% Chromium and 8-10.5% Nickel

Grade 316

16-18% Chromium; 10-14% Nickel; 2-3% Molybdenum

Mesh – The distance between two adjacent parallel wires, measured from centre to centre of the wires

Diameter – Thickness of the wire

Mesh – The number of openings per lineal inch

SWG – Standard wire gauge

Aperture– The distance between two adjacent wires

Diameter– The thickness of the wire before weaving

Pitch– The distance between the middle point of two adjacent wires or the sum of the aperture width and the wire diameter.

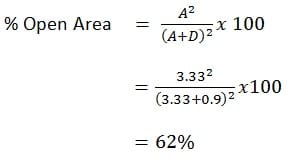

% Open Area– The ratio of the area of the aperture to the area of the mesh expressed in percentage terms

Warp– All wires running lengthwise of the cloth as woven

Weft– All wires running across the cloth as woven

Aperture

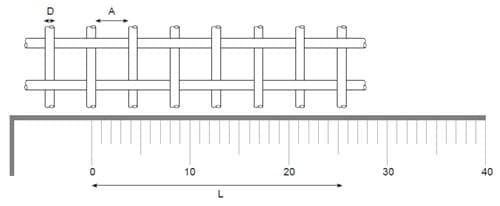

Calculating the aperture

- Count of a convenient number of apertures(N)

- Measure the length covered by the N apertures(L)

- Measure the wire diameter(D)

- The average aperture(A)

Working example of calculating the aperture of 6/20 woven wire mesh

- Number of apertures counted – N = 6

- Length covered by apertures centre to centre – L = 25.4mm

- Diameter of wire- D = 0.9mm

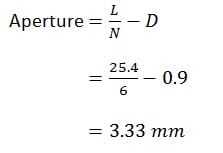

- Aperture

The woven wire is identified as 3.33mm aperture / 0.9mm diameter

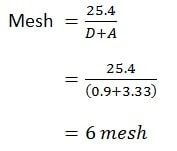

Mesh Count

If the aperture and the diameter are known the mesh count can be determined

Percentage Open Area

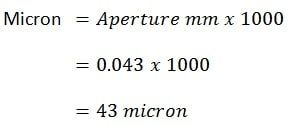

Micron conversion

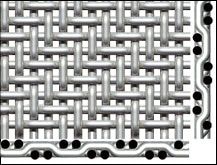

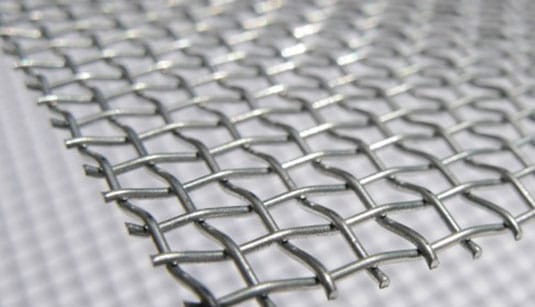

Plain Weave

The most common and simplest weaves.Each warp wire (wire running parallel to the length of the cloth) passes alternatively over and under the wires running transversly through the cloth at 90 degree angles.

Intercrimp Weave

Has extra crimps in warp and weft wires between intersections.

Lock Crimp Weave

Is produced with pre-crimped wire. Lock crimp weave is stabilised by a notch or bump at the wire intersections.

Twill Weave

Is Produced by passing each fill wire alternatively over and under two warp wires.