In stock

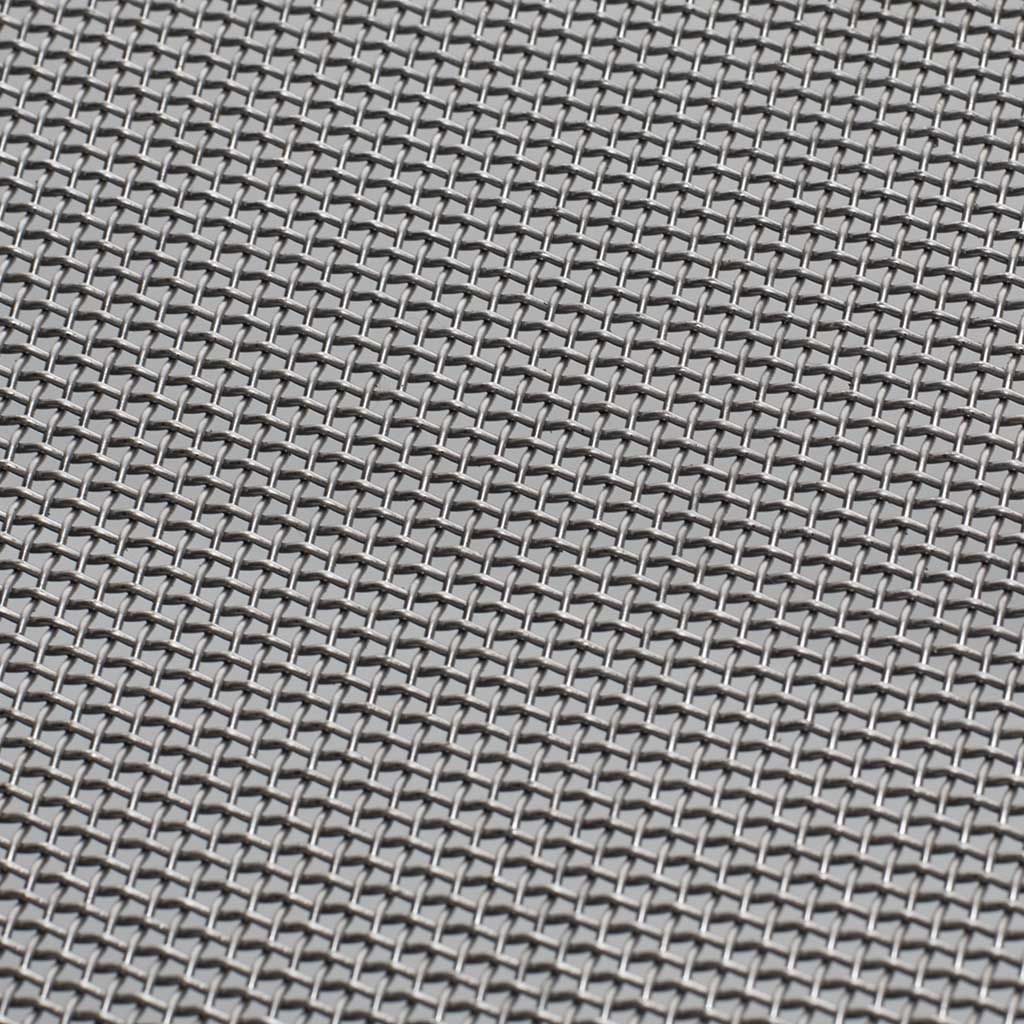

Stainless steel woven wire mesh is ideal for many architectural applications, both internally and externally. By selecting stainless steel you will utilise its numerous benefits including:

Architectural applications include external mesh facades, ceilings, solar shading, mesh balustrades, decorative screens, partitions, wall cladding, joinery & cabinetry.

Stocked Product Specifications ready for same day despatch

SSWM stock an extensive range of stainless steel mesh for- refer to the following stock guides:

For more information on determining woven mesh, terminology, formulas and the different types of weaves see more information or our latest post on our blog ‘The Ins and Outs of Woven Mesh‘.

Minimum Sale Quantities

915mm, 1220mm & 1245mm width – 2 lineal meters. Then sold in multiples of 1 metre.

1550mm width – 10 lineal meters. Then sold in multiples of 10 metres.

| PARENT CODE | MESH | SWG | APERTURE MM | WIRE DIAMETER MM | APPROX % OPEN | TECHNICAL DATA SHEET | REQUEST A QUOTE |

|---|

| PARENT CODE | MESH | SWG | APERTURE MM | WIRE DIAMETER MM | APPROX % OPEN | TECHNICAL DATA SHEET | REQUEST A QUOTE |

|---|

| PARENT CODE | MESH | SWG | APERTURE MM | WIRE DIAMETER MM | APPROX % OPEN | GRADE | TECHNICAL DATA SHEET | REQUEST A QUOTE |

|---|

Mesh is Tested / Manufactured to:

|

ASTM International (formerly American Society for Testing and Materials) ✔ ASTM E2016-15 ‘Standard Specification for Industrial Woven Wire Cloth’ Manufactured to |

|

Technical Data Sheets ✔ Refer to SSWM Technical Data Sheets for further Standards / Testing information and which of the above are relevant to the mesh that you have selected |

Our stocked size is 1200 x 2400mm.

However for large volumes panels can be custom made.

No. We only cut across the width of the roll once.

To enable speed to market we have all specifications in pre-cut 2 m rolls in 1245mm wide and 10m rolls in widths above 1550mm which are ready to be dispatched upon order.

We accept payment via PayPal or direct deposit EFT. We have a strict policy of not taking credit card details over the phone

Absolutely, we welcome you to use your own freight company.

If we receive your order before 9am, it will be dispatched on same day.

5 lineal metres and increments of 5 lineal metres

1245mm wide – 2 lineal metres and increments of 1 lineal metre

1550mm wide – 10 lineal metres and increments of 10 lineal metres

1830mm wide – 10 lineal metres and increments of 10 lineal metres

We have a datasheet for each product item, these include a to scale image, specifications, dimensions and weights. These are found on the website in the far right column of the product tables. We also include a link to the relevant datasheet in all quotes, proformas and invoices.

Mesh – The number of openings per lineal inch.

SWG – Standard wire gauge

Aperture- The distance between two adjacent wires

Diameter- The thickness of the wire before weaving

Pitch- The distance between the middle point of two adjacent wires or the sum of the aperture width and the wire diameter.

% Open Area- The ratio of the area of the aperture to the area of the mesh expressed in percentage terms

Weft- All wires running across the cloth as woven

Aperture

Calculating the aperture

Working example of calculating the aperture of 6/20 woven wire mesh

The woven wire is identified as 3.33mm aperture / 0.9mm diameter

Mesh Count

Percentage Open Area

The mesh has a 62% open area

Micron Conversion

Micron (micrometer) is a unit of measure, in which usually only fine mesh under 1mm is referred to. A micron us a thousandth of a millimetre.

In this example 325/48.5, 0.043mm aperture, 0.035mm diameter is used.

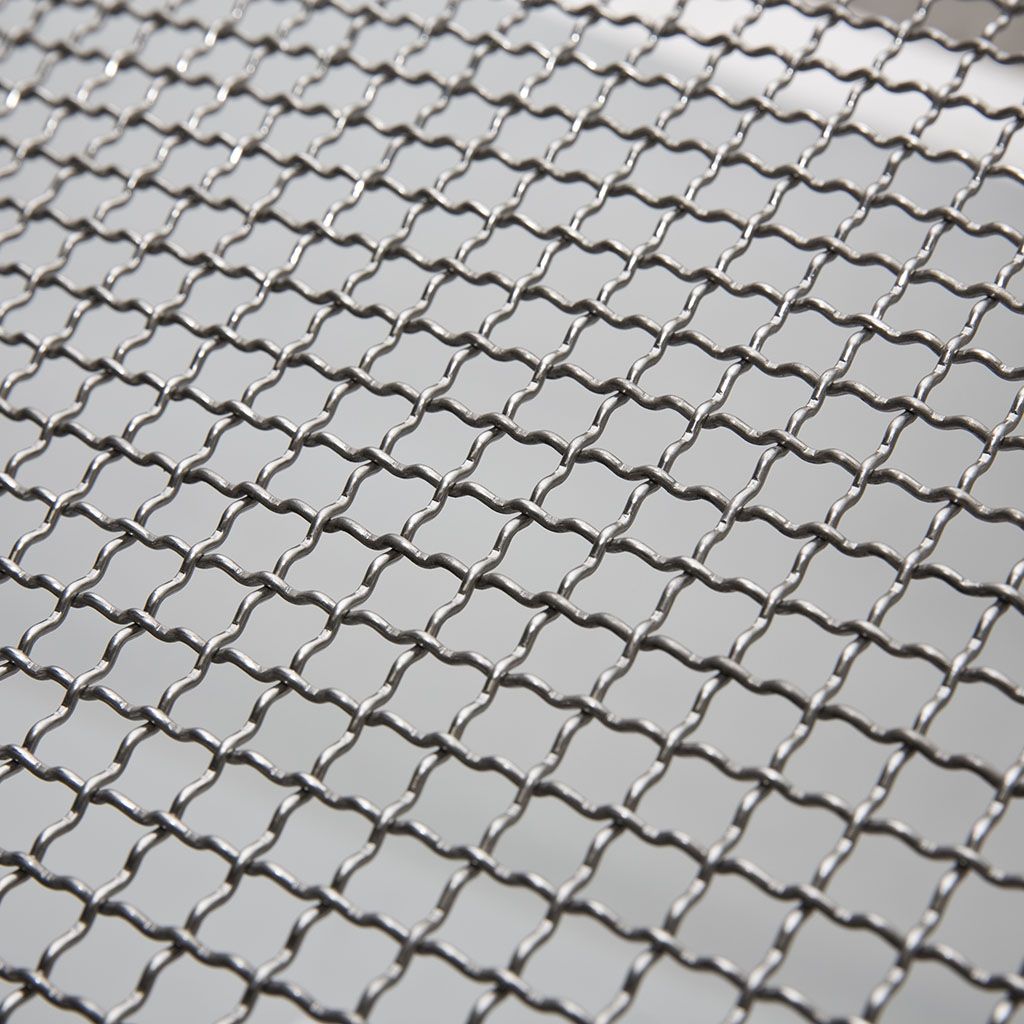

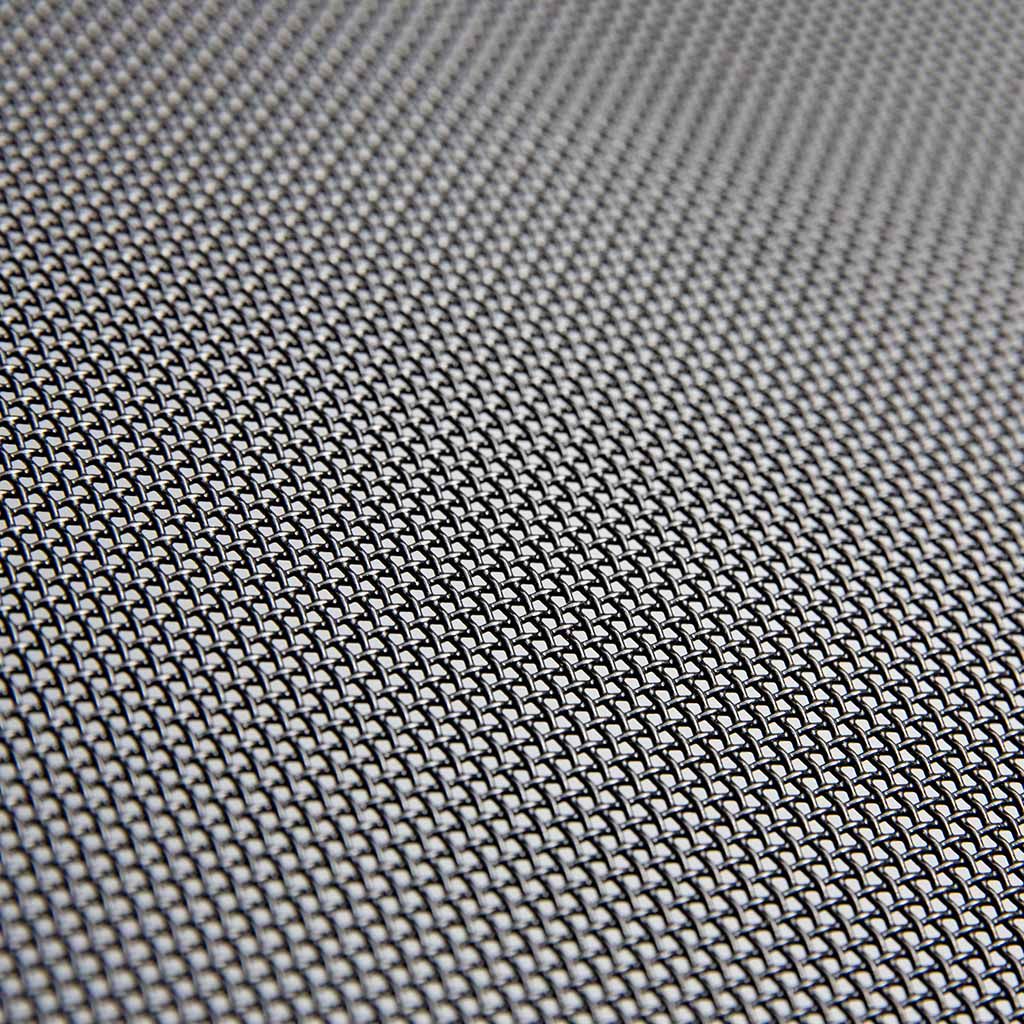

Plain Weave

Has extra crimps in warp and weft wires between intersections.

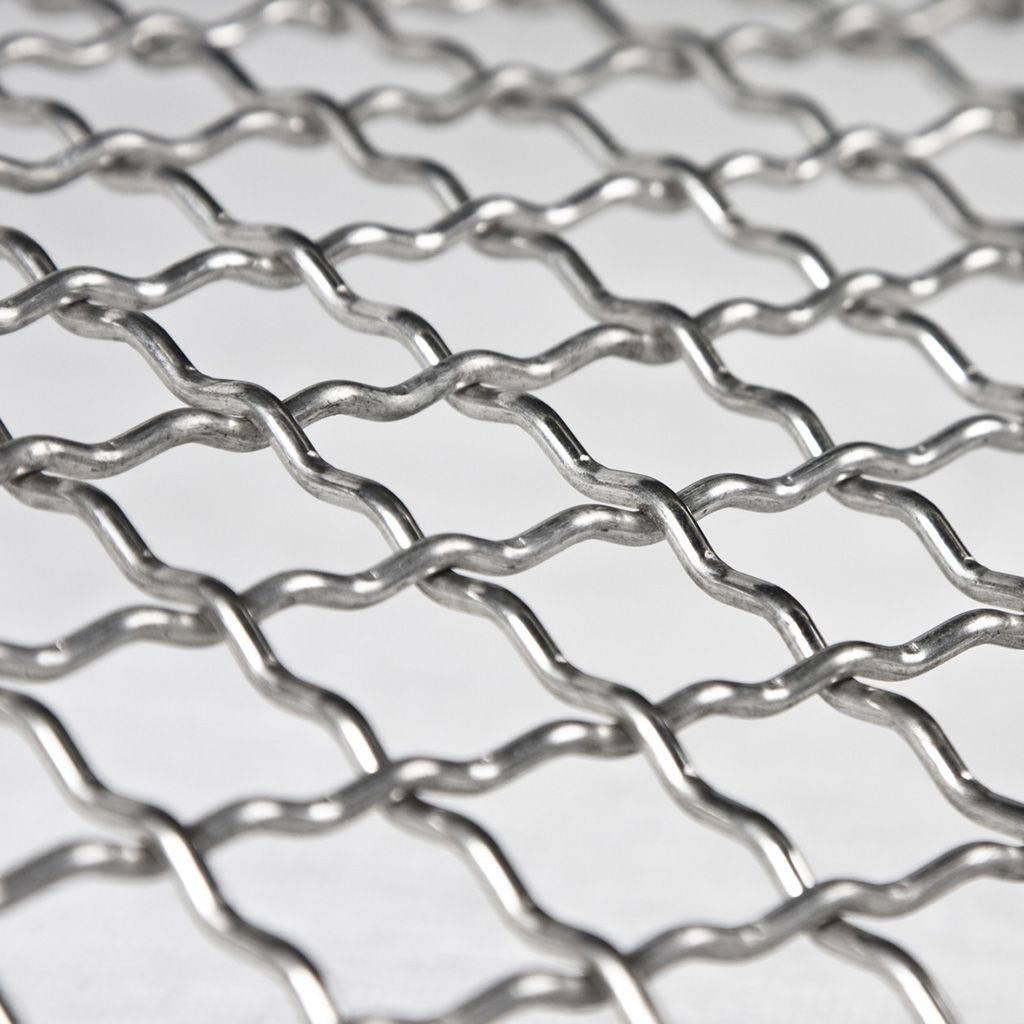

Lock Crimp Weave

Is produced with pre-crimped wire. Lock crimp weave is stabilised by a notch or bump at the wire intersections.

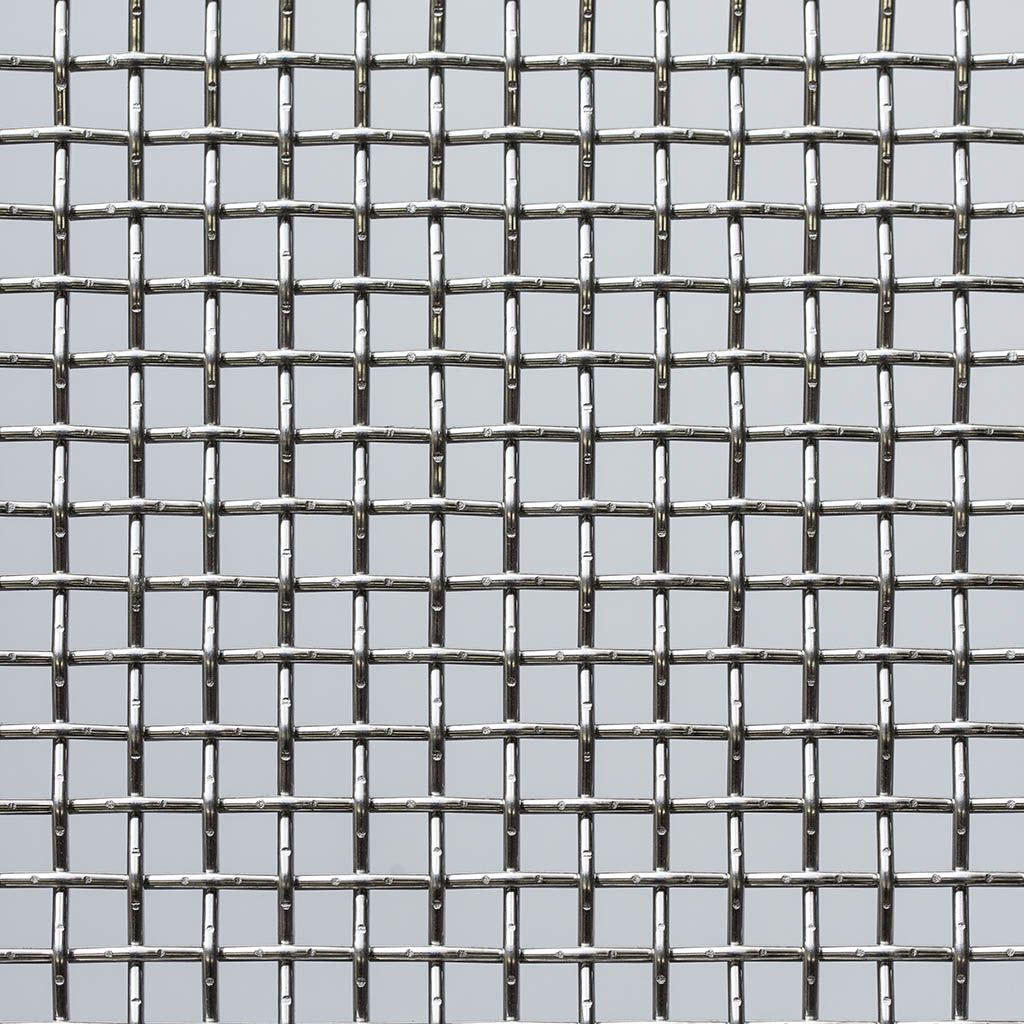

Is Produced by passing each fill wire alternatively over and under two warp wires.

We’ve been supporting local manufacturing and infrastructure projects for over 20 years.

We have been dealing with SSWM for over 9 years. SSWM stock holding is always reliable and ready for us to pick up that day! We have a great strategic relationship and value the referrals that we receive from SSWM.

MPPT ENGINEERING PTY LTD

Paul Jeffery

We are a family business and we love dealing with another family business SSWM. Andrew Greer likes to tell me we can dance on our feet and it’s very true SSWM are incredibly responsive, with a great range and are very customer focused.

MORGANA & SONS PTY LTD

Ben Morgana

We recently renovated a rural property and installed Stainless Steel Bushfire Mesh. The SSWM team were a pleasure to deal with helpful and efficient. We now have a fantastic product installed and I would have no hesitations in recommending SSWM.

BUSHFIRE MESH

John Newman Morris

3 Commercial Court, Tullamarine VIC 3043, Australia

t 1300 304 316 f 1300 305 805

Int t +613 9448 9048 Int f +613 8669 4506

Unit 2/195 Jackson Road, Sunnybank Hills, QLD 4109

P.O Box 358, Tullamarine VIC 3043, Australia

Complete the form below and we will get back to you as soon as possible.