Reinforcing mesh is a crucial building material, its main role is to provide concrete with structural integrity and to improve tensile strength and prevent cracks. Stainless steel is now being used to replace traditional steel more and more as reinforcement for concrete.

The Corrosion Resistance of Stainless Steel Reinforcing Mesh

Stainless steel, in those areas where chlorine is present, is superior in its ability to withstand corrosion (electro chemical reaction) as compared to traditional steels. Not all stainless steels are the same and metallurgists have developed materials that are able to meet the requirements of different operating environments. There are now many examples of where stainless steel has been substituted for traditional steels in highly corrosive environments:

- Progresso Pier, Mexico

- Garrison Crossing Bridge Toronto, Canada

- Pooley Bridge Lakes District, England

- Cala Galdana Bridge Menorca, Spain

- Stonecutter Bridge, Hong Kong

- Go-Between Bridge, Brisbane

- Barnes Creek Bridge Brunie Island, Hobart

- Schaffhausen Bridge, Switzerland

- Victoria Bridge, Brisbane

- Gateway Upgrade Bridge, Brisbane

- Soderstrom Rail Bridge, Stockholm

A Shift in Engineering Knowledge

Structural Engineers are now understanding the different grades of stainless steel that can be used in different environments that can achieve their asset design life. Unlike traditional steel, certain grades of stainless steel are not attacked by chlorine ions and therefore the use of stainless steel doesn’t lead to “Concrete Cancer” (corrosion cracking).

Selecting the right grade of Stainless Steel for your environment is critical to ensure your asset will meet its design life which will result in a lower lifecycle cost. There are many international standards that can be used by Design Engineers to assist them in the use of Stainless Steel for the requirements of Reinforced Concrete including:

- ASTM A276 Standard Specification for Stainless Steel Bar and Shapes

- ASTM A1022 – Standard Specification for Deformed and Plain Stainless-Steel wire and welded wire for Concrete Reinforcement

- BS 6744 – Stainless steel bars, Reinforcement of concrete – Requirements and test methods

What are suitable Stainless Steel Grades for Reinforcement?

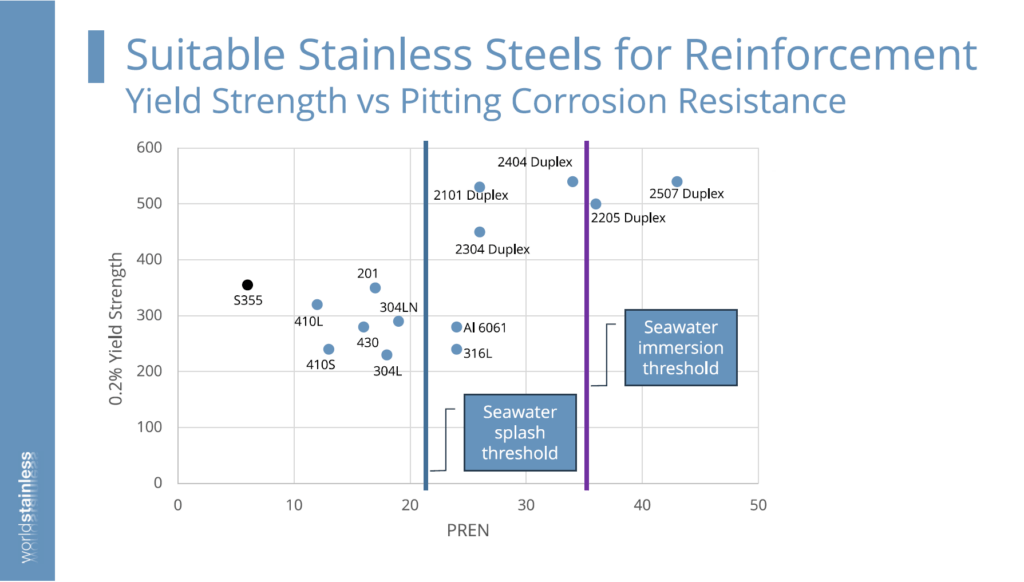

The below graph demonstrates the performance difference between stainless steel grades 304, 316 and Duplex 2205.

The graph demonstrates the differences using PREN (Pitting Resistant Equivalent Number) it is a measure of the relative pitting corrosion resistance of primarily steels in Chloride containing environments.

The formula which determines the PREN is:

PREN = (1xCR%) + (3.3xMo%) + (16xN%)

Source: World Stainless Steel Association

Stainless Steel Reinforcing Mesh Grades & Common Applications

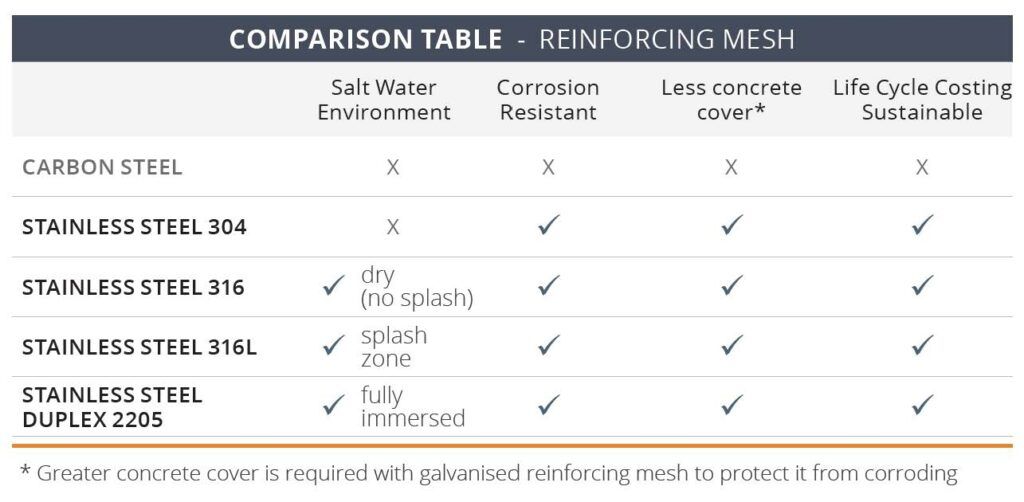

We know that there are different levels of Chlorine ions that can be found in different environments across Australia and for each of these environments there is a grade of stainless steel that will meet the design life and that are commercially available:

- Stainless Steel 304

- Inland locations with low levels of Chlorine ions where critical infrastructure is built with long design life

Application train platform

- Inland locations with low levels of Chlorine ions where critical infrastructure is built with long design life

- Stainless Steel 316

- Commonly used for polluted, industrial and coastal environments in dry areas with no splash

Application concrete crossovers (no splash)

- Commonly used for polluted, industrial and coastal environments in dry areas with no splash

- Stainless Steel 316L

- On shore locations close to Coastlines where critical infrastructure is built (splash zone)

Applications ramps from costal buildings down to sand - Locations away from the coast where salinity exists in the water table, a combination of Submerged and Splash zone with medium erosion rates

Applications Lake boat ramp

- On shore locations close to Coastlines where critical infrastructure is built (splash zone)

- Stainless Steel 316L and Duplex 2205

- Coastal locations where critical infrastructure is required, a combination of Submerged and Splash zone with medium erosion rates

Applications piers, jetties, tunnels and bridges

- Coastal locations where critical infrastructure is required, a combination of Submerged and Splash zone with medium erosion rates

- Duplex 2205

- Offshore locations a combination of Submersed and Splash zone with high erosion rates

Applications oil rigs and wind farms

- Offshore locations a combination of Submersed and Splash zone with high erosion rates

The grades above are referenced in the ASTM A1022 as being suitable for Reinforced Concrete as per section 1.3 of the standard.

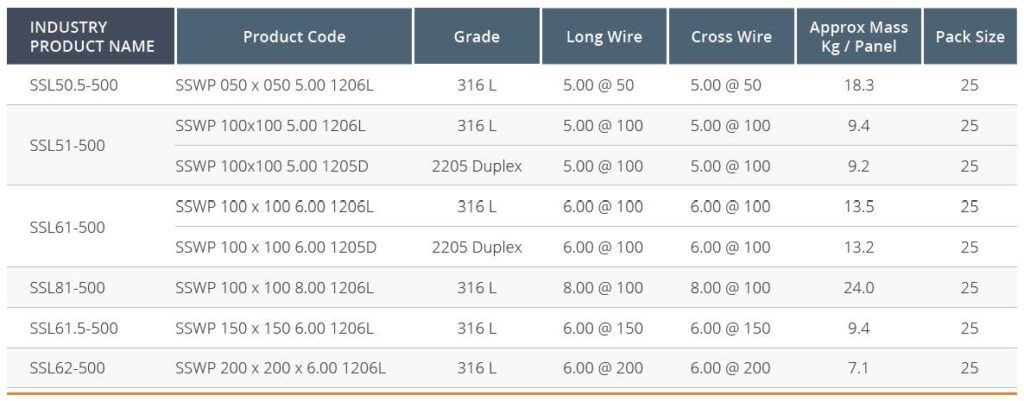

Are the traditional Industry Product Specifications available?

In short the answer is yes. We have developed this handy product specifications table to make your specification easy:|

All panels are 2400 x 1200mm.

SSWM your Stainless Steel Reinforcing Mesh Experts

At SSWM we supply Stainless Steel Mesh that is installed for concrete reinforcing in a diverse range of applications. Our products meet the International Standards for Chemical composition and are tested to the Australian Standards (AS 4671) for Mechanical properties (dimensions and strength).

We understand Stainless Steel Mesh and can assist you to select the most appropriate product for your application. We are a long standing member of ASSDA and with their support we can help you with your difficult questions on grade and application.