When specifying Stainless Steel industrial mesh, what should be considered?

Stainless Steel is best practice for when Industrial Mesh is specified, and it needs to withstand harsh environments and applications. Stainless Steel provides a long-term solution for your project due to its durability. It is therefore important to know and understand the:

- Environment, as this determines which grade of mesh you select

- Application, as this determines which type of mesh you select

Industrial Mesh has a great presence in various industry sectors from construction to defence, energy, government, and manufacturing. To assist our customers, we have developed our range to deliver on the following functions:

- Screening / Filtering

- Structural / Mechanical

- Asset Protection

Stainless Steel Welded Panel, Nepean River & Great River Walk Bridge NSW, Complete Stainless Supplies - Decorative Features

Our Industrial Mesh product range has been developed to include, but is not limited to:

- Stainless Steel Woven Mesh

- Stainless Steel Welded Panels

- Stainless Steel Welded Rolls

- Stainless Steel Perforated Sheets

How is Stainless Steel Mesh superior?

Stainless steel mesh is superior to galvanised mesh and other products, due to its benefits. Put simply “The Lasting Decision”. Stainless steel plays a significant role in modern day society, with endless applications. Stainless steel provides long term performance with minimal maintenance. Of all engineered products, stainless steel has one of the lightest impacts on the environment. By selecting stainless steel, you will utilise its numerous benefits, including:

- Incredibly durable

- Non-corrosive

- Strength

- Life cycle costing

- Low environmental impact

Grade 304 & 316 explained:

Mesh is available in grades 304 & 316. The major difference between Grade 304 and Grade 316, is that Grade 316 has the addition of molybdenum to its chemical composition, which greatly improves its resistance to corrosion, particularly to pitting.

Please be aware that stainless steel still requires cleaning, a simple soap solution will keep your stainless steel sparkling.

Grade 304

18-20% Chromium and 8-10.5% Nickel

For further information please refer to ASSDA’s article 304: The Place to Start

Grade 316

16-18% Chromium; 10-14% Nickel; 2-3% Molybdenum

For further information please refer to ASSDA’s article 316: The First Step Up

Stainless Steel provides excellent formability, its mechanical properties allow for precision and flexibility in its formability. Its material components also allows it to have high weldability, this is how it can deliver on such an extensive range of functions.

What is the function and application of the mesh?

Stainless steel mesh is not only durable but also versatile, it can be formed, bent, welded, cut, fixed, and fabricated to deliver on the following functions and applications:

- Screening / Filtering

- Sieving of foods

Stainless Steel Welded Panel, Fabricated Trolley, Vic Stainless Sales - Food drying processes

- Separation of liquid & solids

- Airflow

- Removal of gasses in

- water treatment plants

- paint industry

- Sieving of foods

- Structural / Mechanical

- Concrete reinforcing

- Gabions

- Machine guarding

- Ember protection

- Asset Protection

- Utilities

- Gutter guard

Stainless Steel Perforated Mesh, Fabricated Product, Vic Stainless Sales - Security fencing

- Rodent & vermin protection

- Bird proofing

- Decorative Features

- Balustrading

- Screening & fencing

Overview of the main types of Stainless Steel industrial mesh

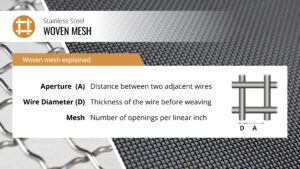

Stainless Steel Woven Wire Mesh is manufactured by weaving longitudinal and transverse wires together. Commercial / Industrial grade mesh is also known as wire cloth and gauze. Due to the weaving of the wire, woven mesh is generally specified for screening / filtering applications.

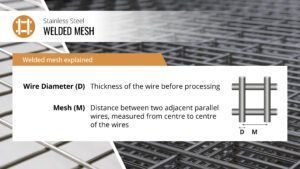

Stainless Steel welded mesh is manufactured by the longitudinal and transverse wires being resistance welded together. Welded mesh has good strength properties and is generally specified for structural / mechanical and asset protection applications.

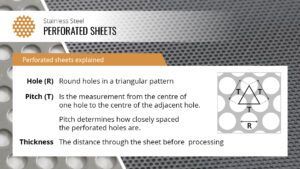

Stainless Steel Perforated Sheets are manufactured by punching or perforating Stainless Steel sheets. SSWM stock the round hole perforations – the most used perforated product. Geometrically, a round hole is the most solid shape. A range of round hole size patterns and open area % are available with strength provided by the round holes in triangular pattern (60O angle).

Technical Information to assist with selection & specification:

Our clear and easy to follow technical information has been designed to make selection and specification easy and will assist you as follows:

Stock guide

SSWM have developed a product selection guide to assist you with selecting the most appropriate welded mesh for your application. It is a great visual resource.

Technical Data Sheets

Contains all the information you require for specifying and ordering.

Samples

10 x 10cm samples can be mailed

Products video

Please watch and enjoy further information about our stainless steel products.

SSWM – your preferred Stainless Steel wire & mesh supplier

SSWM value our relationships with our customers and fabricators, and pride ourselves on understanding your needs.

We bring value to our customers by providing a seamless experience. With our extensive stock of quality assured products and unrivalled service. We listen to our customers and apply our industry knowledge to create solutions.

SSWM stock over 520 Stainless Steel mesh and wire specifications making us Australia’s largest stockist of Stainless Steel wire & mesh. We offer same day despatch (when your order is received by 9am).

Our clear and easy to follow Technical Information will assist you with selecting and specifying the appropriate mesh for your application.

We look forward to hearing from you and supplying your Stainless Steel Mesh requirements.