Australia's largest stockist of stainless steel wire and mesh

Over 20 years of experience in supporting local

manufacturing and infrastructure projects.

Quick Quote

OUR RANGE OF PRODUCTS

We stock an extensive range of stainless steel wire and mesh to meet the specific needs of any project.

Architectural Mesh

Ideal for many architectural applications, both internally & externally.

- Balustrading / Screening

- Joinery / Cabinetry

- Mesh Facades

- Ceilings

- Solar Shading

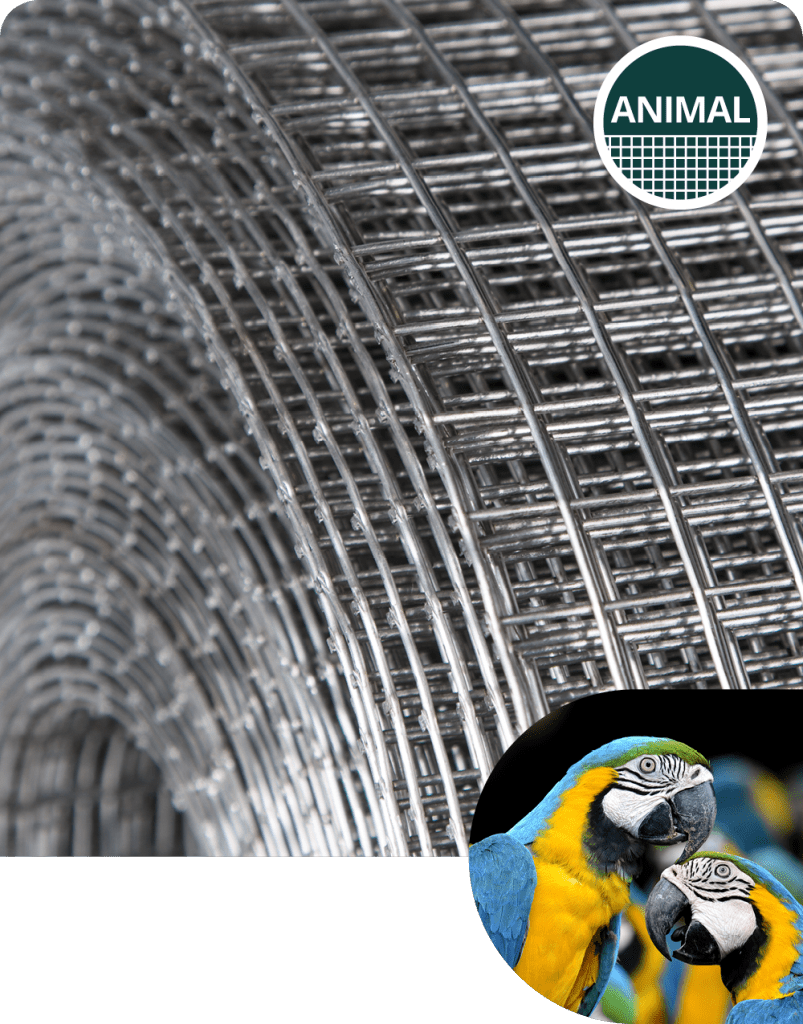

Provides a safe and conformable long lasting environment for animals.

Offers a combination of strength, durability and aesthetic appeal.

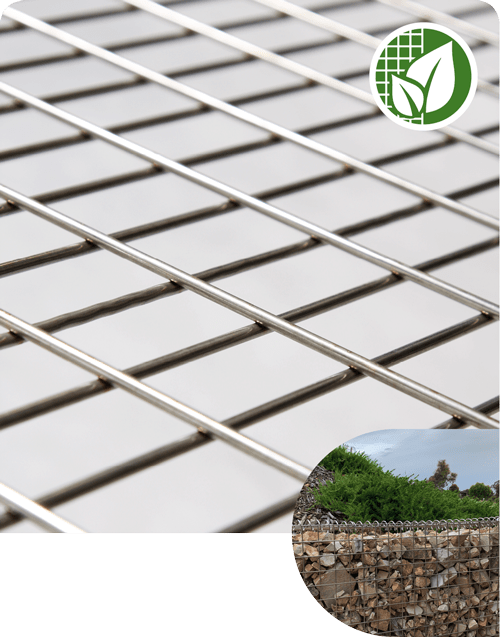

Environmental Mesh is ideal for its applications due to its durability and aesthetic appeal.

- Gabion Mesh

- Living Green Walls

- Tree Guards

- Erosion Control

- Landscaping

It will stand the test of time with Australia’s harsh environment & weather conditions.

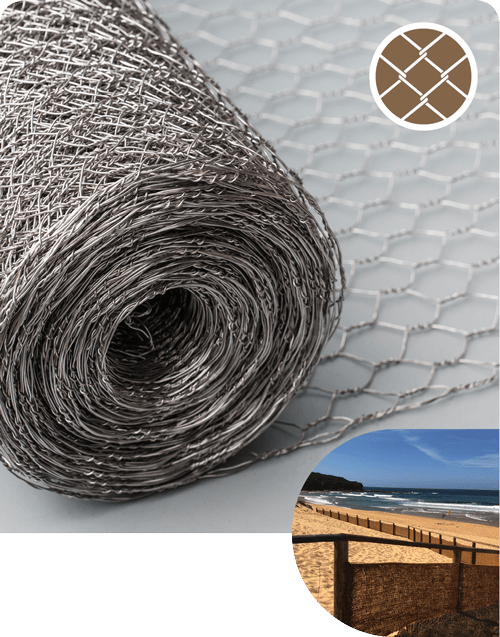

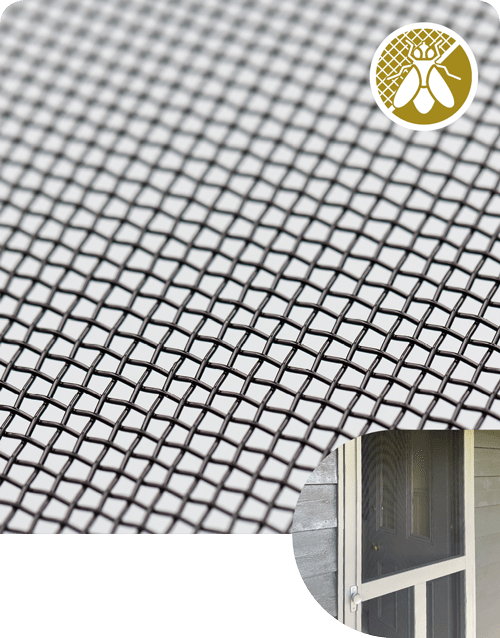

Stainless Steel Window & Door Mesh keeps insects, intruders and embers out whilst letting the breeze in and allowing visibility.

- Insect Mesh

- Pet Mesh

- Security Mesh

We are innovating fixtures and fittings to offer long lasting solutions.

- C Clips & Pliers

- Industrial Wire Staples

- Spirals

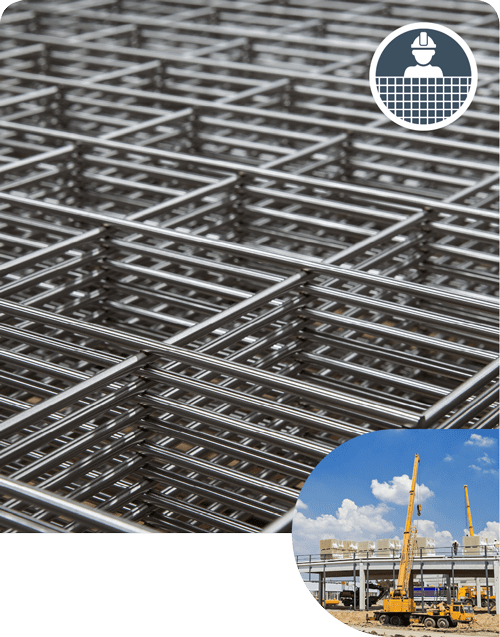

Provides long term performance. Is durable and versatile and used for a range of applications.

Quick Quote

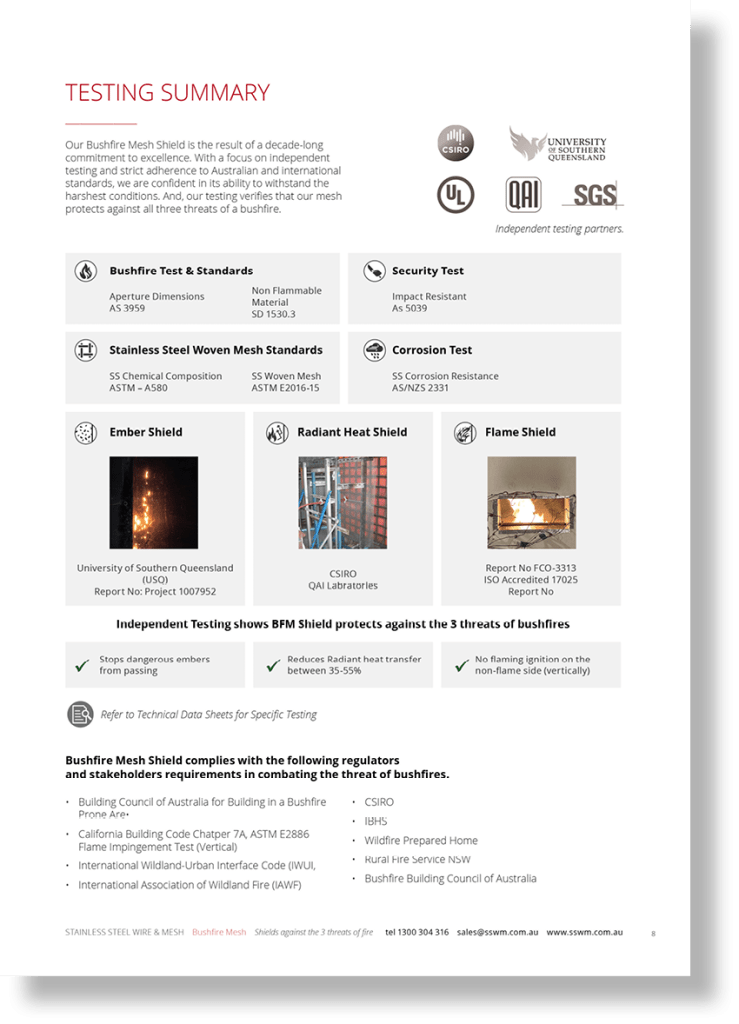

TESTING

Our range of products are independantly tested to ensure the highest standards of quality and performance.

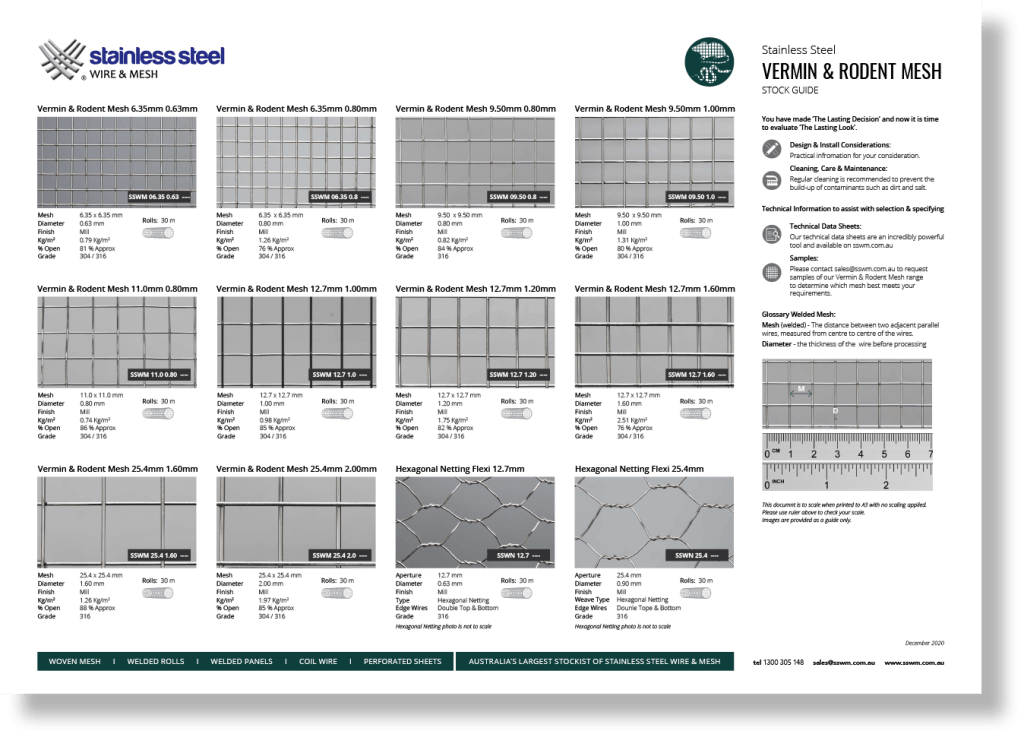

PRODUCT SELECTION GUIDES

Easily navigate our extensive range of products and select which product best meets your requirements with our Product Selection Guides.

Our intuitive tables of technical specifications and our to-scale images make selection and specification straight forward.

TRUSTED BY 1000+

BUSINESSES AROUND AUSTRALIA

We’ve been supporting local manufacturing and infrastructure projects for over 20 years.

We have been dealing with SSWM for over 9 years. SSWM stock holding is always reliable and ready for us to pick up that day! We have a great strategic relationship and value the referrals that we receive from SSWM.

MPPT ENGINEERING PTY LTD

Paul Jeffery

We are a family business and we love dealing with another family business SSWM. Andrew Greer likes to tell me we can dance on our feet and it’s very true SSWM are incredibly responsive, with a great range and are very customer focused.

MORGANA & SONS PTY LTD

Ben Morgana

We recently renovated a rural property and installed Stainless Steel Bushfire Mesh. The SSWM team were a pleasure to deal with helpful and efficient. We now have a fantastic product installed and I would have no hesitations in recommending SSWM.

BUSHFIRE MESH

John Newman Morris

PROJECTS ACROSS AUSTRALIA

From Woodend the the Wimmera, we’ve been working with a range of our clients to…

Coastal Dune Restoration

Northern Beaches, NSW

Stainless Steel Strong Lock

Infrastructure Project

Nepean River Bridge, Penrith, NSW

Stainless Steel Anti Climb Mesh

Asset Protection

Warehouse, NSW

Stainless Steel Louvre Mesh

Western Australia

Mining Site

FREQUENTLY ASKED QUESTIONS

Our stocked size is 1200 x 2400mm.

However for large volumes panels can be custom made.

No. We only cut across the width of the roll once.

To enable speed to market we have all specifications in pre-cut 2 m rolls in 1245mm wide and 10m rolls in widths above 1550mm which are ready to be dispatched upon order.

We accept payment via PayPal or direct deposit EFT. We have a strict policy of not taking credit card details over the phone

Absolutely, we welcome you to use your own freight company.

If we receive your order before 9am, it will be dispatched on same day.

WELDED MESH

5 lineal metres and increments of 5 lineal metres

WOVEN MESH

1245mm wide – 2 lineal metres and increments of 1 lineal metre

1550mm wide – 10 lineal metres and increments of 10 lineal metres

1830mm wide – 10 lineal metres and increments of 10 lineal metres

We have a datasheet for each product item, these include a to scale image, specifications, dimensions and weights. These are found on the website in the far right column of the product tables. We also include a link to the relevant datasheet in all quotes, proformas and invoices.