What is Roof Safety Mesh?

Why is Stainless Steel Roof Safety Mesh Superior to Galvanized?

Roof Safety Mesh is an important product to prevent workplace injuries in Australia. In the Compliance Code: Prevention of Falls in General Construction, Roof Safety Mesh is a part of ‘level 2’ controls, as a Passive Fall Prevention Device. Commercial roofs are required to be built to Industry Standards and these standards take into consideration the typical function of the building.

Stainless Steel can be used in harsh environments, such as beaches. The image to the right shows galvanised roof safety mesh at Brighton Beach, Victoria. The mesh is exposed to harsh coastal, so the galvanised has corroded and rusted overtime, and will need to be replaced. Stainless Steel is the best practice for the Roof Safety Mesh installation, especially in harsh conditions as it lasts longer than the building itself, and requires minimal maintenance in return for long lasting, superior quality performance.

Australian Standards

Roof safety mesh should meet the requirements of AS/NZS 4389:2015 – Safety Mesh. This standard provides a specification for the mesh and for the load testing of the mesh, which involves the dropping of a 166kgm, 1500mm long, 350mm diameter bag onto installed mesh from a height of 1.4m, as seen to the right.

- AS/NZS 4389:2015 ‘Safety Mesh’ exceeds technical requirements & complies to load testing

- Tensile strength of our wire is a minimum 600Mpa exceeding requirement of 450Mpa

- AS 2331.3.1:2001 (R2017) ‘Neutral Salt Spray Test’ PVC Coated tested to 96 hours

Roof Safety Mesh also needs to be compliant with safety standards. This is due to 13% of worker fatalities in Australia are caused by falling from heights. Heights above 2 metres are considered “high risk” so the material installed must be durable, reliable, and long lasting.

Why when specifying the type of material for Roof Safety Mesh must we consider the environment and applications?

The main factor when deciding what material to specify for Roof Safety Mesh, is the environment that the mesh will be exposed to. There are several conditions that we need to consider when selecting the type of Roof Safety Mesh. These are:

- Temperature

- Humidity & Moisture

- Thermal Expansion

- Chemical Exposure

- Dissimilar Metals

The type of Roof Safety Mesh needs to take into consideration these conditions and still deliver the safety performance required for the life of the building.

Applications

Stainless Steel Roof Safety Mesh is commonly used for roofing critical assets and infrastructure. Stainless steel can withstand Australia’s harsh environment including coastal and highly corrosive environments common applications include:

- Warehouses

- Factories

- Shopping Centres

- Schools

- Office Buildings

- Sheds

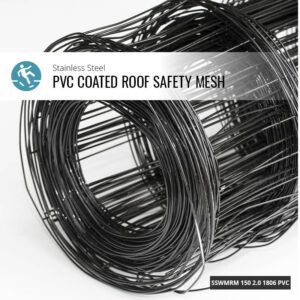

Why did SSWM develop PVC coated Stainless Steel Roof Safety Mesh?

Further information: ASSDA have written a great Technical FAQ on Galvanic / Dissimilar Metal Corrosion

https://www.assda.asn.au/images/PDFs/FAQs/FAQ1.pdf

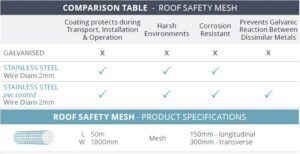

What material can be used for Roof Safety Mesh?

Stainless Steel Roof Safety Mesh takes into consideration the environmental conditions, and still delivers the safety performance required to make it a lasting decision. Stainless Steel has excellent properties over other materials and has the longest life. This means that your Stainless Steel Roof Safety Mesh will last as long as your Roof and will deliver the safety performance requirements over time. Unlike alternative products, such as Galvanized Steel, Stainless Steel is not a surface coating, and its properties can’t be damaged during transport, installation, or operation.

When you consider the costs of Stainless Steel Roof Safety Mesh over time as a percentage when installing on new facilities, it will become the obvious choice. It will last the life of the building, meaning there will be no need to inspect or replace over time. This can? save you tens of thousands of dollars on Inspections and Maintenance. In addition, it will give you Peace of Mind that you have used a product that will make your facility safer when people are working on the roof.

Why you should be specifying Stainless Steel Roof Safety Mesh for your next project?

Make the decision on your next build to use Stainless Steel Roof Safety Mesh and save your client time and money while making it safer for all. Using Stainless Steel Roof Safety Mesh to prevent falls from heights is Best Practice on every level.

References

Please see our previous blog on Roof Safety Mesh and follow the links below for more information

Victoria

Work Safe Victoria: Prevention of falls in general construction

NSW

Work Cover NSW: Safe work on roofs

Part 1: Commercial and Industrial buildings

AUSTRALIA- National

Safe Work Australia: National code of practice for the prevention of falls in general construction

Appendix E of the WorkSafe Victoria document “Prevention of Falls in General Construction” describes the installation of safety mesh